Intermediate Carrier

Precision Chains , a key player in the Sugar Industry for over 30 years.

Our knowledge within the sugar cane processing industry has led us to produce several conveyor chain series to deal with the handling of Sugar Cane across the entire processing spectrum.

The Intermediate Carrier Conveyors have been designed to deal with the highly corrosive nature of the application. This has meant that we've carefully selected the most appropriate materials for the job and have used high grades of stainless steel to help counter the corrosive conditions that the chains will be under.

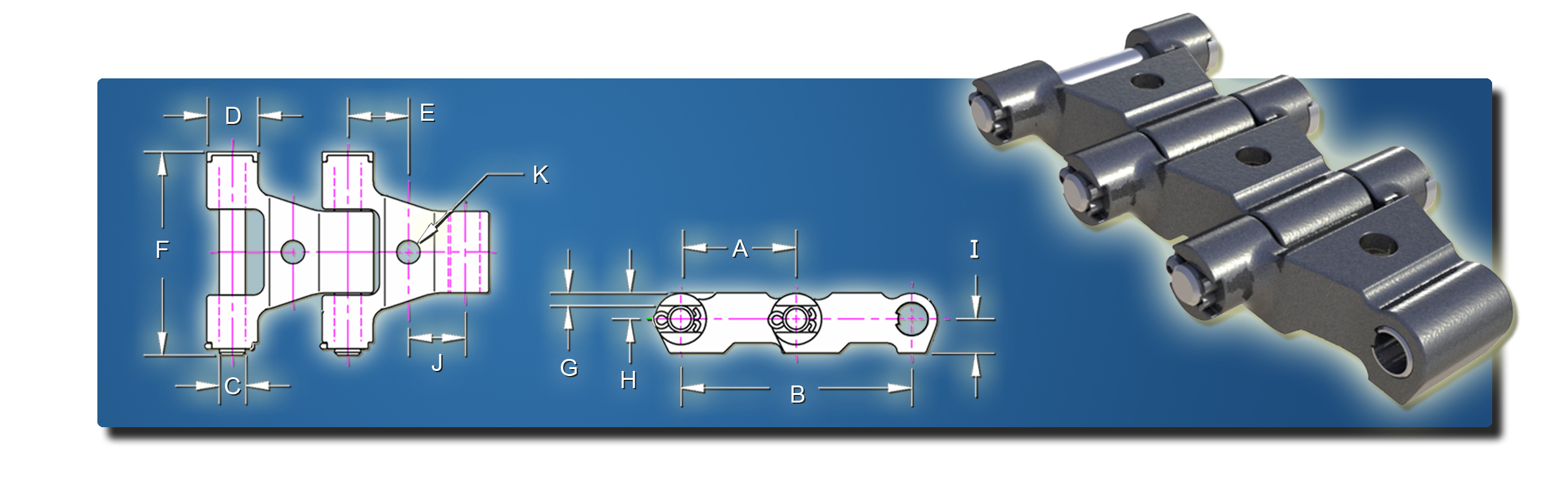

PC 907 E51

This is an all Stainless chain made to resist the corrosion from the sugar solution. It consists of a cast link in grade 300 austenitic stainless, and 410 hardened austenitic stainless bushing and headed stud. Also Available in malleable iron if required.

Packing Length: 40 pitches, 3.22m (10.6 feet).

35,000 lb Tensile Strength19.8 KG/m Weight.

| DIMENSION | A | B | C | D | E | F | G | H | I | J | K |

| mm | 80.52 | 161.04 | 16.0 dia | 35.7 dia | 42.42 | 142.0 | 10.0 | 18.29 | 23.88 | 38.1 | 16.2 dia |

| INCHES | 3.17 | 6.34 | 0.63 dia | 1.406 dia | 1.67 | 5.59 | 0.394 | 0.72 | 0.94 | 1.5 | 0.638 dia |

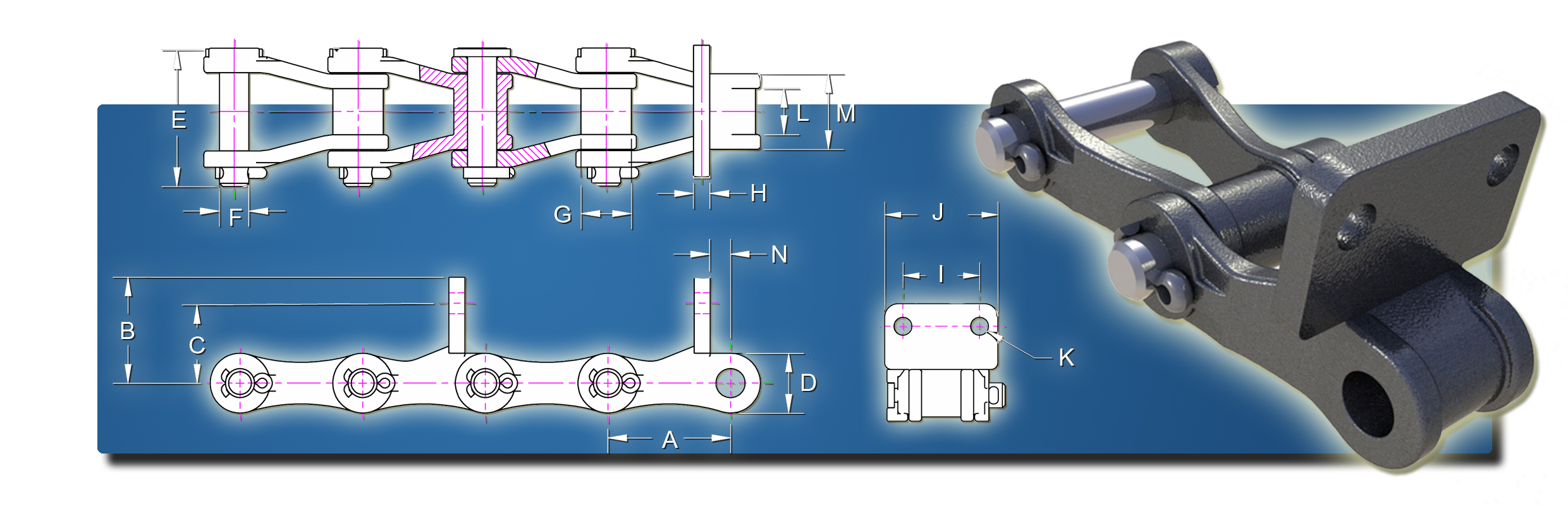

PC 4103

Another all stainless chain resistant to corrosion from sugar solution. The cast block, stud and split pin are all austenitic stainless steel. The F29 attachment can be positioned as required.

Packing Length: 40 pitches, 3.12m (10.25 feet).

122 KN ( 27,500 lb ) Tensile Strength

9.22 kg/m Weight of Plain Chain0.50 kg additional Weight of F29 attachment.

| DIMENSION | A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| mm | 78.1 | 67.5 | 50.8 | 38.1 | 90.5 | 19.05 dia | 31.75 dia | 10.3 | 56.4 | 83.4 | 14.0 dia | 29.0 | 47.6 | 14.0 |

| INCH | 3.075 | 2.66 | 2.0 | 1.5 | 3.56 | 0.75 dia | 1.25 dia | 0.41 | 2.22 | 3.28 | 0.55 dia | 1.14 | 1.87 | 0.55 |

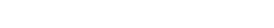

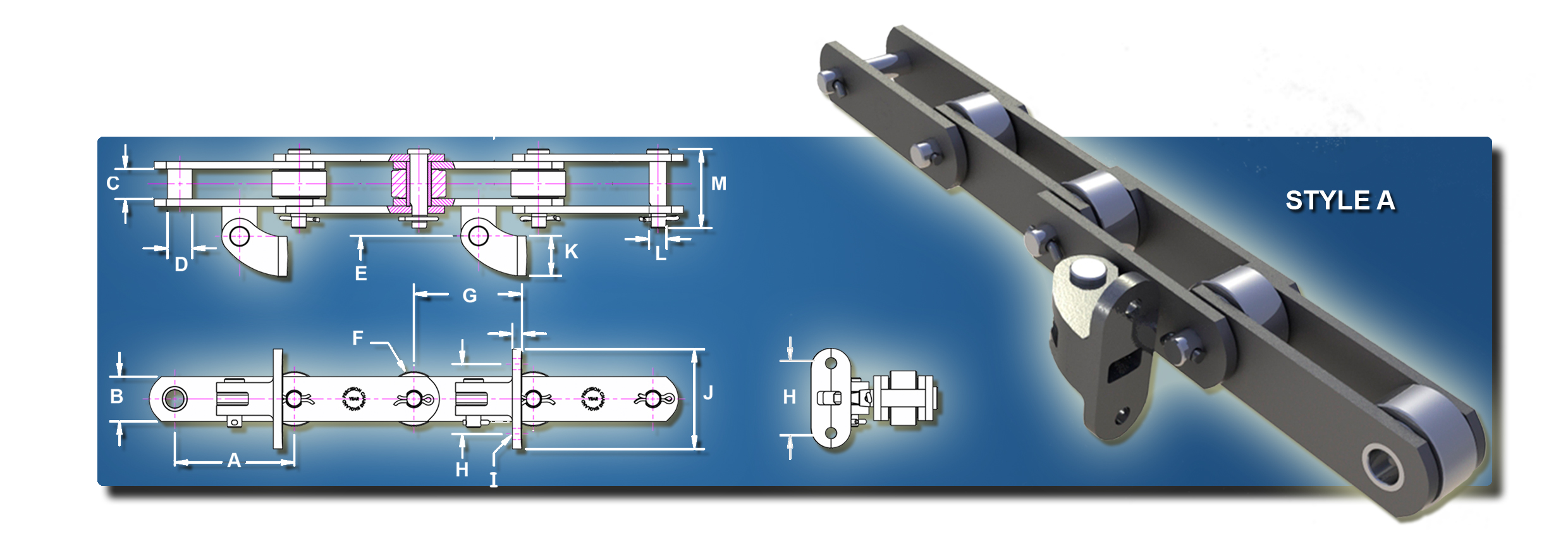

AS2 Series

These chains are also commonly used on the Bagasse conveyor series and come in two alternative styles. One compromised of flat inner and outer bar components (Style A) , and the other assembled using a cranked sidebar instead (Style B). Both chains are more than capable for the application but the design is down to our client preference.

Components

The stud is manufactured from chrome molybdenium alloy steel, hardened and induction hardened on its full circumference. There is a single flat placed on the inside of the link so that corners, which are a stress raiser, are positioned in an area of the sidebar which is in low tension.

The seamless steel bush has a particularly heavy deoth of case hardening to match the stud. No flats are used in order to avoid stress raisers in the area of the sidebar which is in the maximum tension. Rollers are bossed and either hardened or case hardened. We also manufacture all these chains with stud and bush in 431 hardened stainless steel, a grade particularly resistant to corrosion from sugar solutions

| REFERENCE | CHAIN STYLE | TENSILE STRENGTH | STUD/ BUSH BEARING AREA (mm sqr) | RATED WORKING VALUE KN | WEIGHT OF PLAIN CHAIN kg/m | WEIGHT OF LUG + FLIGHT kg | FLIGHT REFERENCE | |

| KN | 1000 lb | |||||||

| PC 1130 | B | 152 | 34 | 970 | 24.2 | 12.7 | 1.5 | 2C |

| PC 9060 | A | 311 | 70 | 1100 | 20.7 | 16.7 | 1.0 | 21C |

| PC 9060 | B | 311 | 70 | 1100 | 27.2 | 16.7 | 1.0 | 21C |

| PC 2164 | B | 378 | 85 | 1200 | 30.0 | 18.3 | 1.3 | 2C |

| PC 9061 | A | 378 | 85 | 1100 | 20.7 | 16.5 | 0.9 | 21C |

| PC 9061 | B | 378 | 85 | 1100 | 27.2 | 16.5 | 0.9 | 21C |

| PC 2184-2 | B | 445 | 100 | 1200 | 30.0 | 19.4 | 1.3 | 2C |

| PC 1796 | A | 445 | 100 | 1300 | 24.1 | 18.8 | 1.0 | 21C |

| PC 1796 | B | 445 | 100 | 1300 | 31.8 | 18.8 | 1.0 | 21C |

| PC 8184-2 | B | 756 | 170 | 1800 | 34.5 | 21.1 | 1.3 | 2C |

| PC 8184 | B | 890 | 200 | 1800 | 45.3 | 23.6 | 1.3 | 2C |

Key Dimensions

| DIMENSION | CHAIN REFERENCE | ||||||||||

| 1130 B | 9060 A | 9060 B | 2184 B | 9061 A | 9061 B | 2184-2 B | 1796 A | 1796 B | 8184 B | 8184-2 B | |

| A | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 203.2 | 203.2 |

| B | 50.8 | 50.8 | 50.8 | 50.8 | 57.15 | 57.15 | 55.6 | 57.15 | 57.15 | 76.2 | 69.85 |

| C | 38.1 | 38.1 | 38.1 | 34.93 | 38.1 | 38.1 | 34.93 | 38.1 | 38.1 | 46.03 | 46.03 |

| D | 28.58 | 28.58 | 28.58 | 31.75 | 28.58 | 28.58 | 31.75 | 31.75 | 31.75 | 38.1 | 38.1 |

| E | 87 | 88.9 | 88.9 | 92.08 | 88.9 | 88.9 | 92.08 | 88.9 | 88.9 | 106.35 | 106.35 |

| F | 63.5 | 69.85 | 69.85 | 76.2 | 69.85 | 69.85 | 76.2 | 69.85 | 69.85 | 88.9 | 88.9 |

| G | 142.88 | 111.13 | 111.13 | 142.88 | 111.13 | 111.13 | 142.88 | 111.13 | 111.13 | 168.28 | 168.28 |

| H | 88.9 | 82.55 | 82.55 | 88.9 | 82.55 | 82.55 | 88.9 | 82.55 | 82.55 | 88.9 | 88.9 |

| I | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 |

| J | 127 | 114.3 | 114.3 | 127 | 114.3 | 114.3 | 127 | 114.3 | 114.3 | 127 | 127 |

| K | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 | 50.8 |

| L | 19.05 | 19.05 | 19.05 | 22.23 | 19.05 | 19.05 | 22.23 | 22.23 | 22.23 | 25.4 | 25.4 |

| M | 84.2 | 96 | 96 | 93.73 | 96 | 96 | 96.52 | 100.6 | 100.6 | 122.94 | 122.94 |

****** Currently Available ******

X Series Drop Forged Chains (X458, X678, X698)

09060 Sugar Cane Conveyor Chain, Plain Chain

09060 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style A

09060 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style B

09060 Sugar Cane Conveyor Chain, With integral K2 Attachment

All available with Stainless Steel Pin, Bush and Roller

09061 Sugar Cane Conveyor Chain, Plain Chain

09061 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style A

09061 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style B

09061 Sugar Cane Conveyor Chain, With integral K2 Attachment

All available with Stainless Steel Pin, Bush and Roller

09063 Sugar Cane Conveyor Chain, Plain Chain

09063 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style A

09063 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style B

09063 Sugar Cane Conveyor Chain, With integral K2 Attachment

All available with Stainless Steel Pin, Bush and Roller

1796 Sugar Cane Conveyor Chain, Plain Chain

1796 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style A

1796 Sugar Cane Conveyor Chain, AS42 Chain with Flight Wing - Style B

1796 Sugar Cane Conveyor Chain, With integral K2 Attachment

All available with Stainless Steel Pin, Bush and Roller